Software Components

We develop highly-specialized software components for the additive manufacturing process. The components are modularly-structured and offer support along the entire process chain – from the product idea to the supplying of the finished product. They can be integrated into the existing software platforms (e.g. CAD providers) or delivered as a stand-alone software suite.

SUPPORT MODULE

Additive.Support

The Cornerstone: Stable Support Geometries. Whoever would like to obtain good final results in additive manufacturing needs both the right manufacturing strategy as well as also optimal support geometries. Thus, the Additive.Support module covers not just the standard industry support geometry types, but rather offers many process-related improvements. The algorithm in Additive.Support helps to save materials and construction time without compromising stability.

SLICING MODULE

Additive.Core

The Centerpiece: Calculation and Processing of Slice Data. In the case of complex components, the calculation and optimization of slice data result in enormous data quantities which quickly push the user’s PC hardware to its limits. The Additive.Core module is high-performing while nonetheless requiring extremely-low resource consumption. Even very largescale geometries can be calculated on customary industry notebooks. The resulting neutral file format can be used for various additive manufacturing processes and by diverse system manufacturers.

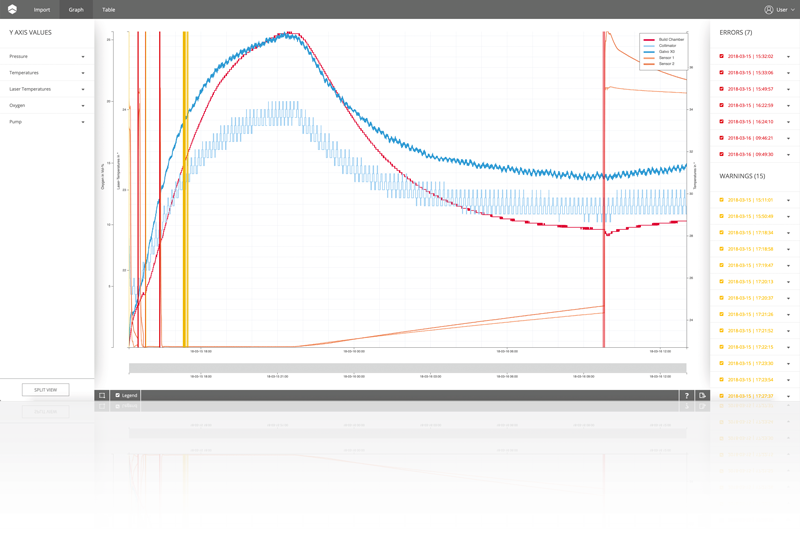

SENSOR LOG MODULE

Additive.Log

The eye: detailed construction job analysis. In order to obtain constantly-good results in component quality, not only good data processing is important. Even during the actual construction process in the 3D printer, there are many factors which can have a signifi cant infl uence on the results. In order to be informed regarding the processes in the machine, our Additive.Log module offers a detailed documentation of the machine’s sensory data. It enables an analysis of componentspecifi c data across the entire additive manufacturing process.

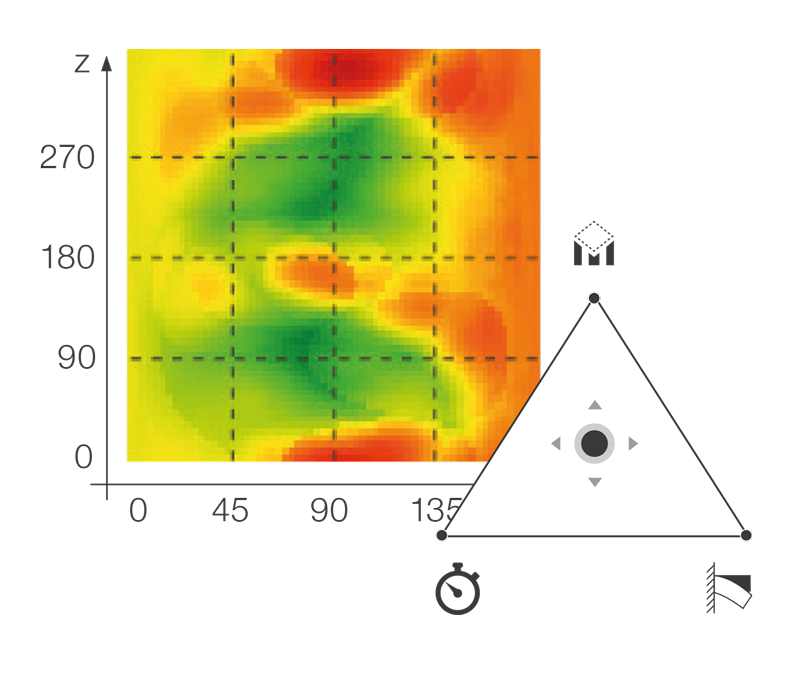

ORIENTATION MODULE

Additive.Optimo

The Foundation: AM-Optimal Component Orientation. The vision of additive manufacturing is additive-specific design and component layout based upon the criteria required by the respective AM-technology. However, as the preparer of the data, one is frequently confronted with components that have been constructed based upon classical criteria. For additive manufacturing, generally other manufacturing criteria are nonetheless valid. Additive.Optimo enables the fast selection of suitable component orientation based upon the quality criteria of the additive manufacturing technology that has been selected in order to enable the attainment of the best manufacturing results for these component families.