Industries

Time is Money – Regardless of the Industry.

Therefore, companies and complete industries are looking for alternative manufacturing processes and workflows. Additive manufacturing stands for design freedom and efficiency. So why waste time unnecessarily for data preparation for your 3D-printed parts? With our software solutions, we provide you with efficient and intuitive tools for your successful metal-based additive manufacturing.

YOUR BENEFITS

WITH CADS ADDITIVE

Vendor-Independent

Our software solutions are compatible with the broadest range of Powder Bed Fusion machines.

No Expertise Needed

CADS Additive puts the power of Powder Bed Fusion into your hands.

High-Performance and Resource-Saving

Our specifically-developed algorithms provide you with high performance with low-resource usage. Save time and costs.

CA-x Agnostic

CADS Additive works with native data from most CAD vendors and CAE systems.

Minimize Your Cost-To-Print

Our integrated costing module helps you to find your optimal cost for every print job.

Guided workflow

Our software leads you through data preparation for metal additive manufacturing. Step-by-step and without any special training.

AUTOMOTIVE INDUSTRY

Automotive industry is Demanding More and More Efficiency

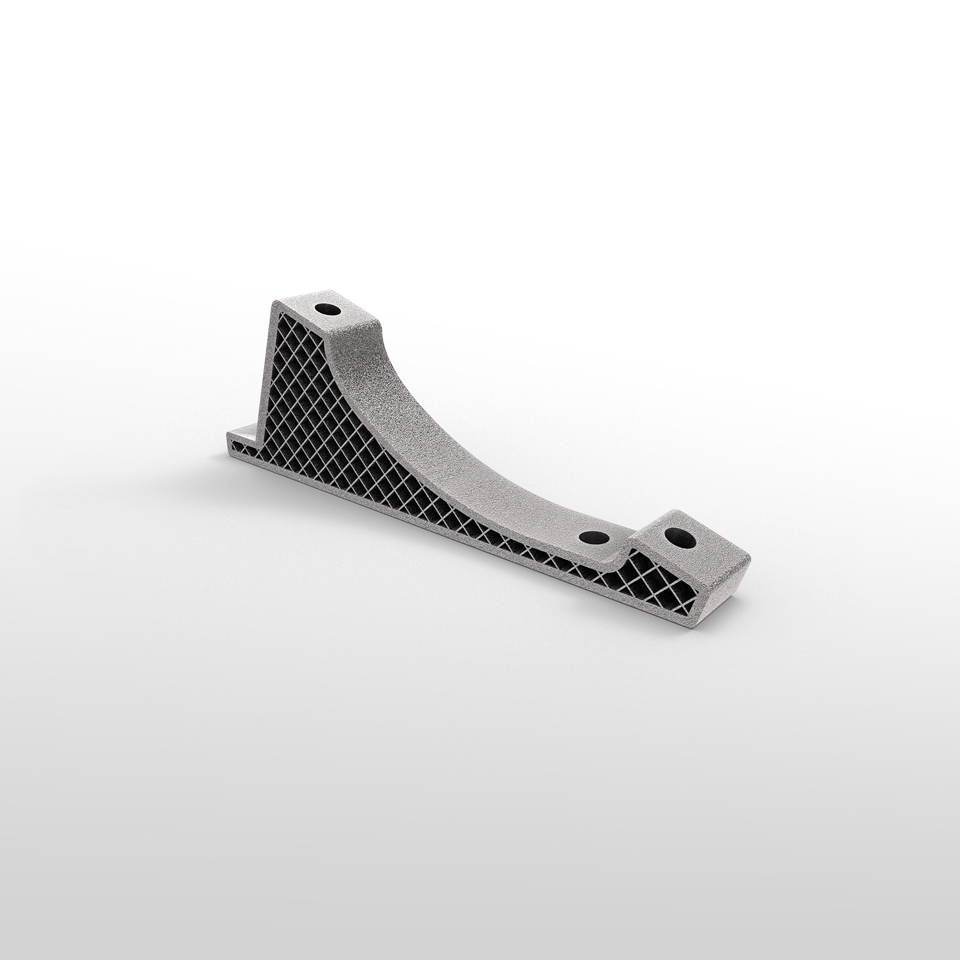

CADS Additive provides companies in the automotive industry with intuitive and efficient software solutions for metal-based 3D-printing. You can take full advantage of additive manufacturing like design freedom and efficiency without being restricted to any forms. We provide you with the features you need for your additive manufacturing success: All common and our in-house-developed support structures will help you to find your optimal support and therefore reduce material usage, time, and costs. Our embedded costing module further enables you to easily calculate the costs for each of your printed parts.

AEROSPACE INDUSTRY

High-Precision Parts and High Quality are Crucial for the Aerospace Industry

CADS Additive provides companies in the aerospace industry with the world’s most intuitive data preparation software for additive manufacturing. The whole project team is able to unleash the full power of Powder Bed Fusion. It can concentrate on developing light-weight and high-quality parts for the aerospace industry without having reservations regarding forms. On the other hand, you still must fulfil strict standards. Our software solutions allow you to prepare your data for additive manufacturing intuitively, step-by-step, and without any special training.

MEDICAL INDUSTRY

Fast Manufacturing and High Precision of Individualized Parts

Small, complex, and personalized parts are your daily business in the medical industry, high-quality, individualized algorithms and software are ours. Not every operation can be planned far in advance. Accidents are likely to happen unexpectedly. Nevertheless, especially these often have a big impact and call for fast action. On the other hand, innovation and new technologies also drive the medical industry. To fulfil the different demands, different solutions are needed. CADS Additive provides you with these solutions in the form of powerful and efficient software for metallic additive manufacturing.

ENERGY INDUSTRY

Alternative and New Energy Systems Require New Paths in Component Manufacturing

CADS Additive helps companies in the energy industry to manufacture parts that meet today’s requirements for new and alternative energy. Replacing worn components of energy facilities which nonetheless still have the potential to supply regions or even whole countries with energy many more years can be cost- and time-intensive. The same applies to the manufacturing of components or complete plants for alternative energy. For most of these challenges, additive manufacturing is the solution. With our intuitive and efficient software solutions, we can enable you to minimize cost and time expenditures for producing these components.

MECHANICAL ENGINEERING

Mechanical Engineering Faces Massive, Ongoing Changes in Part Requirements

New materials, new composites, or new geometries are just some of today’s challenges for mechanical engineering. However, basics still count the same as they did in past decades. Nevertheless, for the changes this industry has to face, CADS Additive can be part of the solution. Additive manufacturing is shaping the future for most manufacturing topics. We enable you to unleash the full power of this technology. With our software solutions, we can guide you step-by-step through an intuitive workflow in data preparation for additive manufacturing – without any special training being needed.

RAILWAY INDUSTRY

Unleash the Full Potential of the Future of Transportation

CADS Additive enables companies in the railway industry to address the demanding trends regarding the future of transportation. Nowadays, public transportation is one of the most important components for enabling global sustainable living. Therefore, almost every industry is responsible for making a contribution towards change. Additive manufacturing can help you to unleash the full potential of the future of transportation and CADS Additivecan help you to set the full power of additive manufacturing free. We can provide you with an efficient and intuitive tool for your successful data preparation for metal-based additive manufacturing.

Don’t find your industry here?