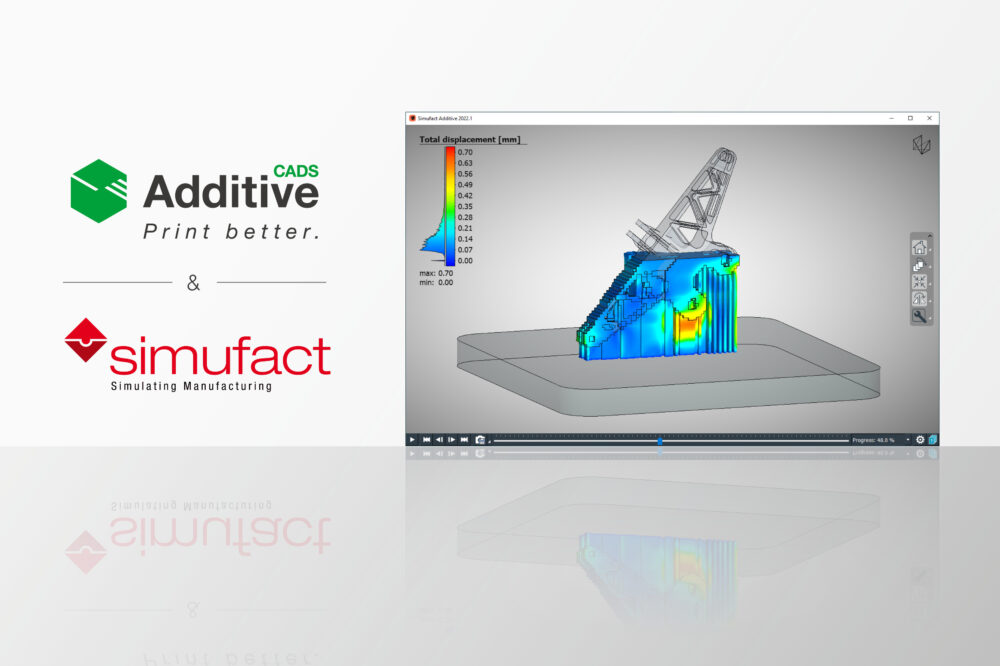

Knowing what the component will look like, already before 3D printing – the Simufact Additive simulation software developed by Simufact Engineering GmbH makes this possible. With the latest release update in December 2022, the Hexagon subsidiary will take its software to the next level: Thanks to the cooperation with CADS Additive, Simufact Additive now works with the Titan.Core build processor. This makes the software more efficient than ever.

The Austrian company CADS Additive has set itself the goal to make data preparation for 3D printing more suitable for everyday use. Processes should be better, faster and more economical. No wonder, then, that it is precisely these advantages that are now giving users of the Simufact Additive simulation software the decisive edge.

Get your Results up to 30 Times Faster

Titan.Core is particularly high-performance. The calculations of layer data for the powder bed fusion process are up to 30 times faster than with comparable build processors. This allows users to make much more economical use of hardware and personnel capacities.

Lower Memory Usage

Slicing and hatching for 3D printing generates huge amounts of data. In addition to the computing time, this also affects the memory utilization of the workstation. With Titan.Core, Simufact Additive now makes things much easier for users and workstations: Thanks to the universally connectable build processor, users now have direct access to their production machines.

„The powerful slicing and hatching of the Titan.Core build processor allows Simufact Additive users to transfer simulation results directly to their 3D printer as manufacturing data.“

Dr.-Ing. Patrick Mehmert, Product Manager, Simufact Engineering

Users Benefit from further Synergies

With the integration of Titan.Core into Simufact Additive, the Hexagon Group and CADS Additive are taking another joint step. Users already have benefited from the synergies of the companies in the past. For example, CADS Additive already provided important algorithms for generating support geometries to Simufact Additive in September 2021.

Users of AM-Studio, CADS Additive’s complete software solution for data preparation, also benefit from the close cooperation. Simufact Additive is integrated in AM-Studio as a standard simulation component.

All Information about CADS Additive and Simufact Engineering

CADS Additive

The motto of CADS Additive: Print better. And that’s exactly what the innovative software components for additive manufacturing help to achieve. Thanks to their high performance and intuitive usability, the solutions not only make working on the 3D printer more pleasant, but also more economical. Today, the company is a 100% subsidiary of the Austrian CADS GmbH.

Simufact Engineering

As a subsidiary of MSC Software, Simufact Engineering is part of the Swedish Hexagon Group. Based in Hamburg, Germany, it is dedicated to the efficient optimization of manufacturing processes. Its simulation software is a benefit for both users and the environment.